When a critical part fails, you can’t afford to wait six months or replace an entire assembly. Send us your drawing or last good sample and get your line running again - fast.

Small Call to Action Headline

A Signature Win -

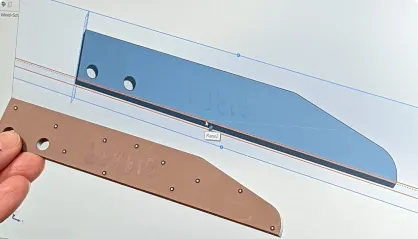

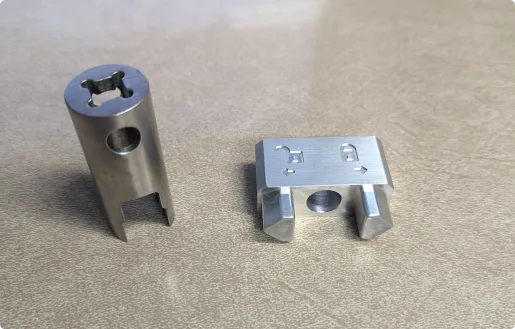

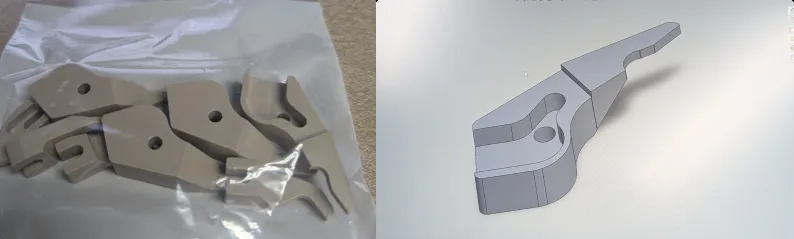

The Bioport Cam

A pharmaceutical client needed replacement cams for a critical isolation port. The OEM quoted a full rebuild kit for $150,000. They only needed three small cams. No one else could make them.

A single last-known-good sample was enough. Truco scanned the geometry, corrected tolerances, and machined a new set from stainless steel. They installed perfectly. No leaks. No shutdowns.

Each unit cost under $2,000. The customer bought nine.

tRUCO ENGINE

When the Line is Down and the Part is Nowhere to Be Found

Production stalls. The part is cracked, undocumented, or outdated. The OEM won’t sell it without a drawing or demands the full assembly at a premium. The clock is ticking.

Here’s what solves it: practical parts, precision fit, and fast action starting with what you have.

Machining With or Without a Drawing

Start with a good drawing or solid part when possible. But if all you’ve got is a worn sample, Truco can still make it work.

Small Batch CNC Machining

Perfect for short runs, discontinued parts, or critical spares.

Compliance-Ready Finishes

Electropolishing, passivation, and stainless surface treatments via trusted local partners.

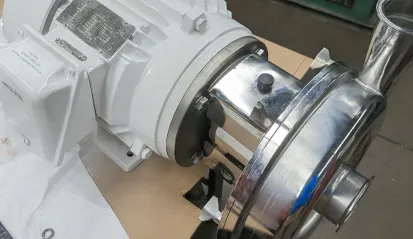

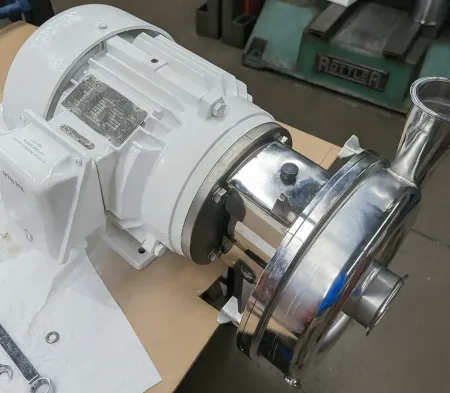

Mixer and Pump Rebuilds

Rebuilt assemblies for preventive maintenance or planned shutdowns tested, cleaned, and ready.

On-Site Troubleshooting

It starts with a phone photo and a practical conversation. No red tape. No ticket system.

What Sets Truco Apart

Not a Job Shop. A Problem Solver.

Some shops need prints. Others need volume. Truco needs a reason to care. If the line is down, the OEM is silent, or the part hasn’t existed in 20 years, that’s when the work begins.

The difference isn’t just in the machines. It’s in the mindset.

Differentiators

Parts are machined from what’s available — a drawing, a sample, or a last known part

Fit and function are verified with the operator before machining begins

Mixer and pump rebuilds are delivered with speed and repeatability

Critical surfaces are tested, polished, and cleaned to spec

Small-batch machining is the default, not the exception

Every part is treated like a system failure waiting to happen — until it’s not

oUR GALLERY

Parts That Didn’t Exist Until

They Were Needed

When a replacement part is no longer available or never had a drawing to begin with, Truco makes it real. From custom cams to crash test latches, every part here was reverse engineered from the ground up.

Signature Win – The Bioport Cam

Proven Results in Regulated and High-Stakes Environments

Every industry has its bottlenecks. In pharmaceuticals, it’s cleanroom compliance. In food, it’s sanitation and uptime. In industrial systems, it’s aging equipment with no documentation. When the job is too precise for guesswork and too urgent for delays, the right partner makes the difference.

Pharmaceutical Manufacturing

Clean-in-place pumps, aseptic mixers, and stainless assemblies reworked with FDA-compliant finishes and precision tolerances. Ideal for shutdowns, audits, and replacement parts with no OEM support.

Food Processing and Packaging

Ravioli rollers, meatball flippers, and custom guides built or rebuilt to spec. Trusted by brands that cannot afford production delays or food safety issues.

Specialty Industrial and R&D

From crash test dummy latches to equipment mounts and sensor brackets, specialized components are reverse engineered with accuracy and repeatability even without a print.

Need a Part Replaced? Start Here.

Have a drawing? A clean sample? Even a worn part? Start with what you have. Upload a photo or CAD file or just schedule a quick call with Andy.

This is how custom machining starts fast, simple, and without the usual roadblocks.

Truco Machine helps manufacturers keep lines running and products moving by delivering practical, precision machining and repair fast, honest, and right the first time.