Mission-Critical Parts. Machined Right.

Some shops want a drawing. Others want a volume order. Truco wants to solve your problem.

Most projects start with a good print or a solid sample — and that’s exactly how it should be. But when the documentation is missing or the OEM won’t help, Truco has the tools and experience to figure it out and keep your line running.

Machining With or Without a Drawing

The fastest way to get your replacement part is with a clear drawing or a good sample to reference — and that’s how most projects start. When a drawing is missing, Truco can use precision 3D scanning and measurement to rebuild a part from a worn or undocumented sample, though this is more involved.

The result is a fully functional replacement, whether the documentation exists or not.

Use Cases:

Bioport cams

Discontinued gears

Custom rollers

Sensor brackets and mounts

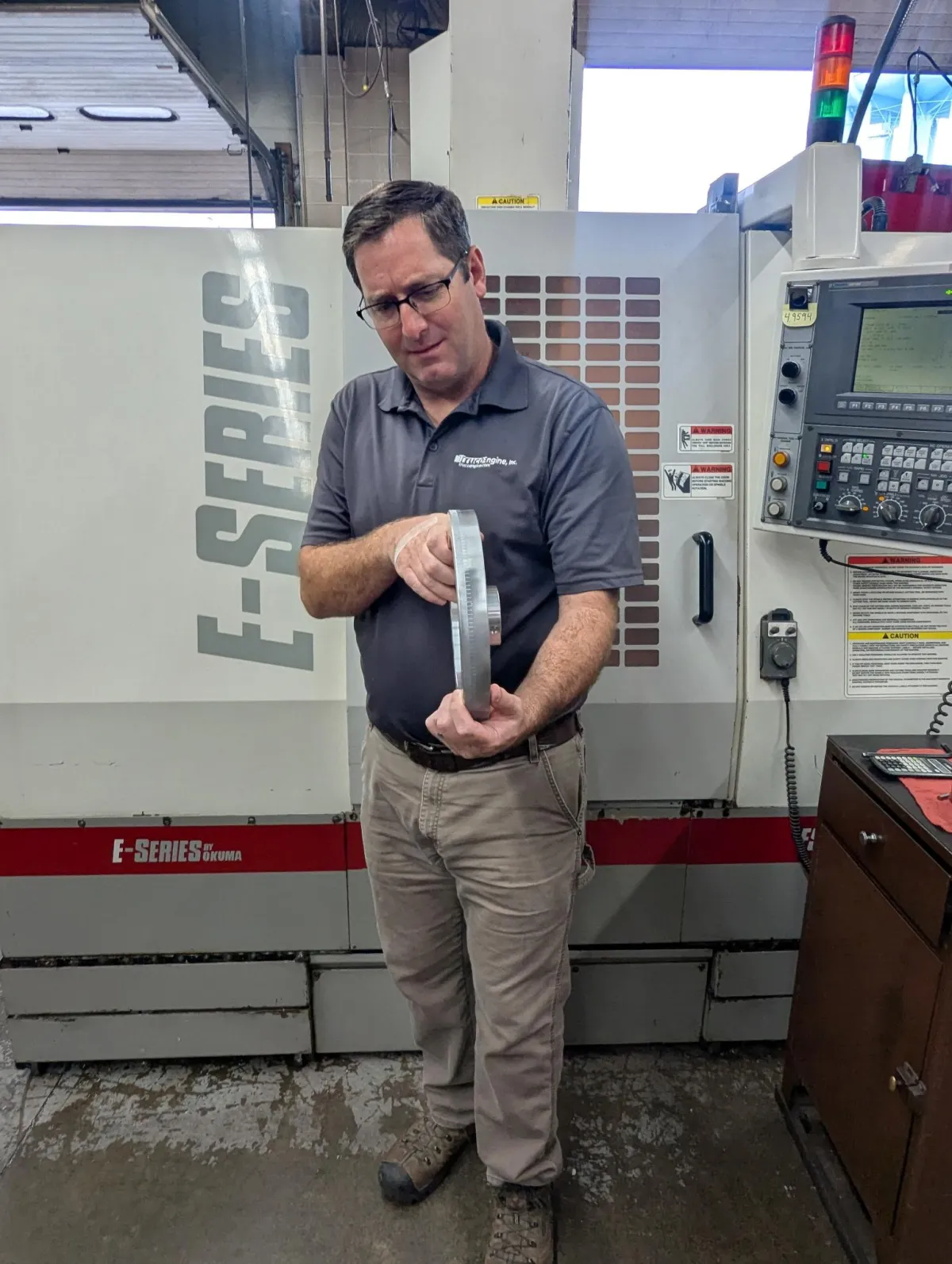

CNC Machining for Short Runs

High mix. Low volume. Mission critical.

Truco machines 1 to 100 parts with the speed and focus larger shops avoid. Whether it’s a one-off prototype or a batch of nine cams, the setup is optimized for precision and repeatability, not mass production.

Use Cases:

Pharma-grade stainless parts

Custom pasta line components

Pre-planned maintenance spares

Replacement seatbelt latch hardware for crash test equipment

FDA-Ready Finishes and Compliance Support

Parts headed into cleanrooms or contact zones are finished with FDA, ISO, and WFI standards in mind.

Truco coordinates polishing, passivation, and electropolishing through trusted local vendors who meet strict compliance protocols. Traceability and documentation can be provided when required.

Services Coordinated:

Electropolishing

Passivation

Clean packaging

Material certifications

Mixer and Pump Rebuilds

When Lightning mixers or CIP pumps go down, downtime is expensive. Truco rebuilds and refits assemblies that would otherwise require a long lead-time OEM order or a full replacement.

Many rebuilds are part of planned preventive maintenance schedules, allowing customers to avoid emergency shutdowns.

These are not off-the-shelf fixes. Every rebuild is fitted, polished, tested, and documented for future reorders.

Supported Equipment:

Lightning mixers

Clean-in-place stainless pumps

Custom impellers and shafts

Flanges, fittings, and seals

On-Site Troubleshooting and Real-World Fit Checks

Most jobs start with a call or a photo texted from the plant floor. Truco doesn’t wait for a perfect brief — the process begins with the problem.

If it helps, Truco will visit the site, speak with the operator, and physically test the prototype before final machining begins. Fit and function come first.

Need Something Machined That Shouldn’t Exist?

Start with what you have. A broken part. A rough sketch. A shutdown window. Truco builds the rest.

Truco Machine helps manufacturers keep lines running and products moving by delivering practical, precision machining and repair fast, honest, and right the first time.